Compactors

Why choose a compactor?

Discover your ideal compactor solution

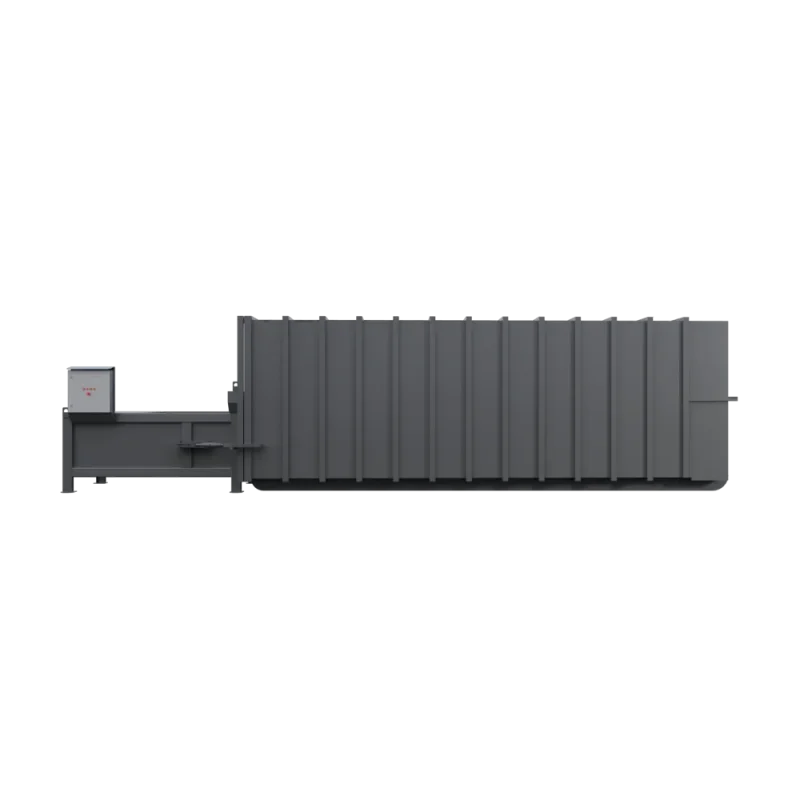

Mobile compactors

Stationary compactors

Save money and reduce your CO2e with BRA-IN

Heading for loop

A deeper dive into waste compactors: An essential asset

An effective solution to this challenge lies in the investment of trash compactors. Let’s explore the mechanics of trash compactors, their capability to handle various waste types, their capacity, and their effectiveness in waste management.

How does a compactor work?

A compactor is a motorised machine designed to reduce waste volume by compressing it.

Here’s a step-by-step rundown of how it operates:

- Loading: The waste is loaded into the compactor’s container.

- Compression: When the machine is activated, the electrically and hydraulically controlled horizontal press plate compresses the waste into the container, effectively reducing its volume.

- Collection: Once the waste is compacted, either the container or the entire compactor is collected, depending on whether you are using a stationary or mobile compactor. The waste is then transported for recycling or incineration, depending on the type of waste.

The extent to which the waste volume is reduced depends on the type of waste, the compactor’s capacity, and its pressing force. Certain specific models, such as polystyrene compactors, can reduce waste volume by up to 98%, highlighting the efficiency of this waste management solution.

What types of waste can be compacted?

Compactors are capable of handling diverse waste types such as:

- Cardboard and cardboard boxes

- Paper: Shredded paper, paper bags and newspapers.

- Plastic: Soft and hard plastic.

- Other materials: Approved wood fragments, metals and cans.

Please contact us for more information if you have a specific waste type that isn’t listed here.

Specialised compactors cater to specific waste types, ensuring efficient compaction and disposal.

How much waste can a compactor handle?

The capacity of trash compactors varies depending on their size and the type of waste:

- Mobile compactor: Typically handles 2-8 tons of waste.

- Stationary compactor: Can typically accommodate 3-10 tons of waste.

- Horizontal baler: Around 2-3 tons of waste daily, depending on the type of waste.

- Vertical baler: Approximately 20kg-800kg per bale. We recommend emptying a baler 1-2 times per week.

Compactors offer various compaction ratios to handle more waste efficiently.

Can a compactor reduce waste volume?

Absolutely! Compactors can:

- Reduce volume: Waste volume can be reduced by a ratio of 5:1 or more, leading to less frequent waste pickups.

- Save space: By compressing waste you save valuable space in waste disposal areas

- Be cost-effective: By reducing waste pickups, businesses can save costs.

Incorporating a compactor: What business owners need to know

Compactors have become indispensable for medium to large businesses seeking to manage their waste efficiently. However, the integration of this equipment calls for a thorough understanding of the space requirements, safety measures, and how they dovetail into existing waste management systems.

Installation space

Base/floor preparation: Compactors require a solid concrete base to withstand the weight and secure the equipment. For most roll-off applications, a surface dimension of 3-5 metres wide by 7-14 metres in length is essential, though compacting skips have a smaller footprint.

Height clearance: A minimum height clearance of typically 7-8 metres is needed for mobile compactors, while small outdoor compactors require a minimum height clearance of 9 metres.

Integration into existing systems:

Ease of integration: Incorporating compactors and balers into existing waste management strategies is often straightforward and can be handled with ease. Various compactor options are available that can seamlessly integrate with your existing system, aided by sensor technology to reduce waste collection frequency.

Handling multiple waste streams: Modern waste compactors are designed to handle a wide range of waste types including dry, wet, bulky, and mixed waste streams.

Site preparation

Electrical access: The proximity of electrical service impacts the installation cost. Solar-powered compactors are alternatives where electrical service is lacking.

Hauler access: The site should be free of overhead obstructions, with ample room for hauliers to manoeuvre safely in and out of the premises.

Industries that use compactors

Compactors are widely used across a range of industries, each benefiting from their versatile applications.

- Manufacturing companies efficiently reduce bulk industrial waste and enhance waste handling processes

- Retailers utilize compactors to minimize landfill waste by compacting packaging materials for sustainable disposal.

- Hospitality & healthcare industries rely on compactors for safe management of mixed waste, including food scraps and medical waste.

- Distribution centres optimizes space by compacting shipping materials, ensuring streamlined operations.

Importance of compactors

- Reduced trash volume: Compaction decreases the volume of waste, leading to fewer pickups and reduced disposal costs.

- Lowered transportation costs: With fewer pickups needed, businesses save on transportation costs and logistical planning.

- Reduced CO2 emissions: Fewer pickups directly contribute to lower carbon emissions, supporting sustainability goals.

Most common questions & answers

Fill in the form and we will contact you

Any Questions? Get in touch